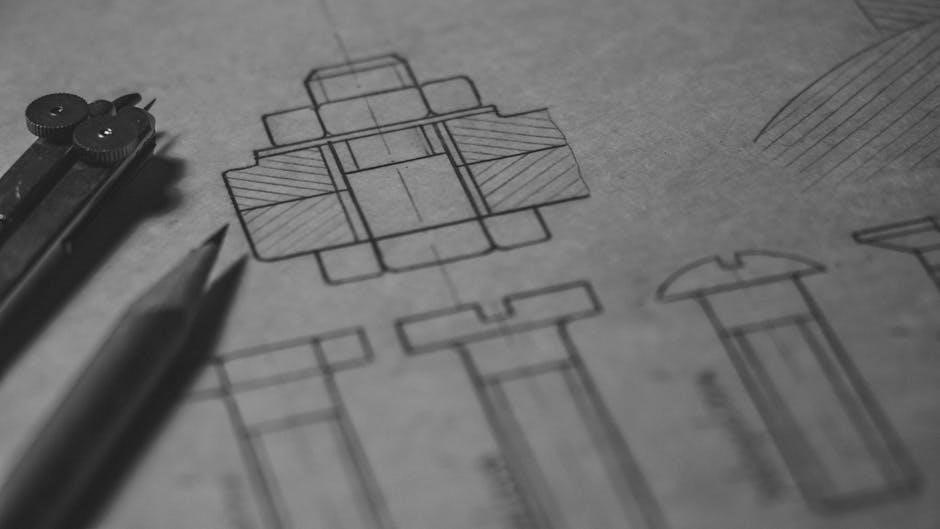

manual transaxle diagram

A manual transaxle diagram illustrates the integrated system combining transmission, axle, and differential, essential for understanding how power is transmitted from the engine to the wheels efficiently.

1.1 Definition of a Manual Transaxle

A manual transaxle is a compact, integrated mechanical system that combines the functions of a transmission, axle, and differential into a single unit. It is designed to transmit power from the engine to the wheels while providing gear ratio options for efficient driving. This setup is commonly used in rear-wheel-drive and mid-engine configurations, offering improved weight distribution and reduced unsprung mass.

1.2 Importance of Understanding the Diagram

Understanding a manual transaxle diagram is crucial for comprehending how the system operates. It provides a visual representation of components like gears, synchronizers, and differential, enabling drivers and mechanics to identify parts and their interactions. This knowledge aids in maintenance, troubleshooting, and performance optimization, ensuring the transaxle functions efficiently and prolongs the vehicle’s longevity.

Components of a Manual Transaxle

A manual transaxle consists of key components like gears, shafts, synchronizers, differential, and axle parts, all working together to transfer power from the engine to the wheels efficiently.

2.1 Gears and Shafts

In a manual transaxle, gears and shafts are critical for enabling speed and torque adjustments. The input shaft connects to the clutch, while the output shaft links to the differential. Gears on these shafts engage in various combinations to provide multiple speed ratios, allowing the vehicle to adapt to different driving conditions efficiently.

2.2 Synchronizers and Their Function

Synchronizers in a manual transaxle facilitate smooth gear engagement by aligning the rotation of gears and shafts. They ensure that gears mesh without grinding, reducing wear and tear. Synchronizers operate by equalizing the speed of the gear and shaft before locking them together, enabling seamless shifting and maintaining driver control during acceleration and deceleration.

2.3 Differential and Axle Components

The differential in a manual transaxle distributes power between the two wheels, allowing them to rotate at different speeds during turns. It consists of pinion gears and a differential case, ensuring smooth torque delivery. Axle components, including half-shafts, connect the differential to the wheels, enabling efficient power transfer while maintaining traction and stability during various driving conditions.

How a Manual Transaxle Works

A manual transaxle transfers engine torque through gears and shafts, controlled by the driver via clutch and shifter, enabling precise power delivery to the wheels.

3.1 Torque Flow from Engine to Wheels

Torque generated by the engine flows through the clutch and input shaft to the gearbox. Gears and synchronizers engage to transmit power via the output shaft to the differential, which splits torque to the axles, delivering it to the wheels. This efficient flow ensures smooth power delivery and optimal vehicle performance.

3.2 Role of the Clutch in Transaxle Operation

The clutch is a critical component that temporarily disengages the engine from the manual transaxle, allowing smooth gear shifts without damage to the transmission. When the clutch pedal is pressed, it releases the clutch disc, interrupting torque flow. This enables seamless transition between gears, ensuring efficient and controlled power delivery during acceleration and deceleration.

Manual Transaxle Diagram Explained

A manual transaxle diagram visually represents the components and their interactions, providing a clear understanding of how the transmission, axle, and differential work together to transmit power from the engine to the wheels efficiently.

4.1 Visual Representation of Components

The manual transaxle diagram provides a detailed visual breakdown of its components, including gears, shafts, synchronizers, and the differential. This representation helps in understanding the physical arrangement and interactions between parts, making it easier to identify how power is transmitted from the engine to the wheels. The diagram is essential for educational purposes and troubleshooting, offering a clear overview of the system’s inner workings.

4.2 Interaction Between Gears and Synchronizers

In a manual transaxle, gears and synchronizers work together to enable smooth shifting between speeds. The synchronizers align the rotation of the gears and collar, ensuring they match speeds before engaging. This interaction prevents grinding and allows for seamless transitions between gears. The diagram highlights how the synchronizer engages with the collar and gear, facilitating efficient power transfer and maintaining control during gear changes. This mechanism is crucial for smooth operation.

Gear Shifting Mechanics

Gear shifting involves engaging and disengaging gears through the clutch and synchronizers. Proper synchronization ensures smooth transitions between gear ratios, optimizing performance and control during acceleration and deceleration.

5.1 Synchronizer Operation During Shifting

During gear shifting, synchronizers engage to align the speed of the gear and shaft, ensuring smooth transitions. They prevent gear clashing by temporarily locking the gear teeth, allowing precise alignment before full engagement. This mechanism minimizes wear and enhances driver control, making shifting efficient and seamless across all gear ratios.

5.2 Gear Ratio Impact on Performance

Gear ratios significantly influence vehicle performance by optimizing speed and torque. Lower ratios enhance acceleration in low-speed conditions, while higher ratios improve top speed and fuel efficiency. A well-designed gear ratio setup ensures balanced power delivery, making it crucial for both everyday driving and high-performance applications in manual transaxle systems.

Applications of Manual Transaxle

Manual transaxles are widely used in sports cars for optimal weight distribution and in rear-engine vehicles like the Volkswagen Beetle and Porsche 911 for enhanced performance.

6.1 Use in Sports Cars for Weight Distribution

Sports cars often utilize manual transaxles to achieve better weight distribution by placing the transmission and differential at the rear, enhancing handling and stability during high-performance driving.

6.2 Examples of Vehicles with Manual Transaxle

Notable vehicles featuring manual transaxles include the Porsche 911, Chevrolet Corvette C8, and Ferrari FF. These vehicles benefit from the transaxle’s weight distribution and performance advantages, making them iconic in automotive engineering for their efficiency and drivetrain integration.

Maintenance and Repair Tips

Regular inspection of fluid levels and component wear is crucial. Lubrication of gears and shafts ensures smooth operation, while prompt replacement of worn parts prevents further damage.

7.1 Regular Inspection of Transaxle Components

Regular inspection of manual transaxle components ensures optimal performance. Check for wear on gears, synchronizers, and bearings. Inspect the clutch and differential for signs of damage or excessive wear; Proper lubrication levels must be maintained to prevent overheating and premature wear. Addressing issues early prevents costly repairs and extends the lifespan of the transaxle system.

7.2 Lubrication and Fluid Check Guidelines

Proper lubrication and fluid checks are crucial for maintaining the manual transaxle. Use the specified transmission fluid to ensure gears and bearings operate smoothly. Regularly inspect fluid levels and condition, topping up as needed. Replace the fluid every 30,000 to 60,000 miles to prevent contamination and wear. Clean or replace the filter to maintain optimal performance and extend component life.

Common Issues and Troubleshooting

Common issues include worn clutch symptoms, such as slippage or difficulty shifting, and hard shifting problems, often due to faulty synchronizers or low fluid levels. Early diagnosis is key to preventing further damage and ensuring smooth transaxle operation.

8.1 Diagnosing Worn Clutch Symptoms

A worn clutch in a manual transaxle often causes symptoms like slippage, difficulty shifting gears, or a burning smell. These issues can lead to inconsistent power delivery and potential damage to other components. Regular inspection and prompt replacement are crucial to maintain smooth operation and prevent further damage to the transmission system.

8.2 Hard Shifting Problems and Solutions

Hard shifting in a manual transaxle is often caused by worn synchronizers or insufficient lubrication. Inspecting and replacing damaged synchronizer parts can resolve this issue. Additionally, ensuring proper lubrication levels and checking for misaligned gears can improve shifting smoothness. Regular maintenance and timely repairs are essential to prevent further complications and maintain optimal transaxle performance.

The manual transaxle diagram provides a clear understanding of its integrated components and operation. Regular maintenance is crucial to ensure optimal performance and extend its service life effectively.

9.1 Summary of Key Points

The manual transaxle diagram highlights the integration of transmission, axle, and differential, showcasing components like gears, shafts, and synchronizers. It illustrates torque flow from the engine, clutch operation, and gear shifting mechanics. Proper maintenance, including lubrication and inspections, is vital for optimal performance. Understanding this system aids in troubleshooting common issues and appreciating its application in various vehicles for efficient power transmission.

9.2 Importance of Proper Maintenance

Regular inspection of gears, shafts, and synchronizers ensures smooth operation and prevents premature wear. Lubrication and fluid checks are crucial for maintaining efficiency and reducing friction. Addressing issues like hard shifting or clutch wear promptly avoids costly repairs and extends the lifespan of the manual transaxle, ensuring reliable performance and driver control over power transmission to the wheels.

Visual Aids and Resources

Utilize detailed manual transaxle diagrams and instructional videos to visualize component interactions, such as gear engagement and torque flow, enhancing understanding of the system’s operation and maintenance.

10.1 Recommended Diagrams and Videos

Explore high-quality manual transaxle diagrams and tutorials that provide step-by-step explanations of components like gears, synchronizers, and differentials; Videos on torque flow and gear shifting mechanics offer practical insights, while interactive 3D models help visualize complex interactions within the system. These resources are essential for both beginners and experienced technicians aiming to deepen their understanding of manual transaxle functionality and maintenance.