how to convert automatic to manual

Converting an automatic to a manual transmission offers a more engaging driving experience but involves complex mechanical changes and significant costs․ It requires careful planning and expertise․

Why Convert to Manual Transmission?

Converting to a manual transmission enhances driving control and precision, offering a more engaging experience․ It provides a direct connection to the vehicle, allowing better feel and responsiveness․ Manual transmissions typically reduce power loss compared to automatics, freeing up horsepower․ Drivers gain a sense of mastery and enjoyment from shifting gears․ Additionally, converting to manual can be a cost-effective option for those seeking a more authentic driving experience without upgrading to a new vehicle․

- Improved control and precision․

- Enhanced driving engagement and satisfaction․

- Reduced power loss, increasing available horsepower․

- Achieve a more authentic driving experience․

Overview of the Conversion Process

Converting an automatic to a manual transmission involves replacing key components and modifying the vehicle’s mechanical systems․ This includes swapping the automatic transmission with a manual gearbox, installing a clutch system, and updating the pedal assembly․ Additionally, the transmission mounts, linkage, and electrical systems may need adjustment․ The process requires precise planning, specialized tools, and often professional expertise to ensure compatibility and functionality․ It is a complex task that demands attention to detail and mechanical knowledge․

Understanding the Differences Between Automatic and Manual Transmissions

Automatic transmissions use a torque converter to connect and disconnect the engine, offering ease of use․ Manual transmissions employ a clutch pedal for driver control, providing a more engaging driving experience․

How Automatic Transmissions Work

Automatic transmissions rely on a torque converter to connect and disconnect the engine from the transmission, eliminating the need for manual clutch control․ Inside, planetary gearsets, bands, and clutches work together to shift gears automatically․ Sensors monitor driving conditions, sending signals to the transmission control module, which activates hydraulic controls to engage the appropriate gear․ This seamless operation allows drivers to focus solely on acceleration and steering, making city driving and heavy traffic more convenient․ The system is designed for ease of use and minimal driver input․

How Manual Transmissions Work

Manual transmissions require driver interaction, using a clutch pedal to disconnect the engine from the transmission and a gearshift to select desired gears․ The clutch engages or disengages engine power, allowing manual gear changes․ Inside, gears and bearings facilitate power transfer to the wheels․ Drivers must synchronize clutch release with accelerator input for smooth shifts․ This direct control enhances driving engagement and efficiency, offering better fuel economy and performance compared to automatics, while also providing a more connected driving experience․

Assessing Feasibility and Requirements

Converting an automatic to manual requires evaluating vehicle compatibility, parts availability, and technical complexity․ Ensure the process aligns with your budget, skill level, and legal requirements․

Vehicle Compatibility and Parts Availability

Vehicle compatibility is crucial for a successful conversion․ Ensure your car’s make and model can support a manual transmission swap․ Availability of donor parts, such as a manual gearbox, clutch system, and pedal assembly, is essential․ Some cars may require custom fabrication if compatible parts aren’t readily available․ Additionally, compatibility with your car’s engine and drivetrain must be verified to ensure smooth operation post-conversion․

Cost and Time Considerations

Converting an automatic to a manual transmission is costly and time-intensive․ The expense often exceeds the value of trading in your automatic car for a manual one․ Parts like the clutch, gearbox, and pedal assembly must be replaced, and labor costs for professional installation can be high․ The process is lengthy, requiring mechanical expertise and legal approvals․ If you’re not experienced, hiring a professional is recommended, further increasing costs․

Tools and Parts Needed for the Conversion

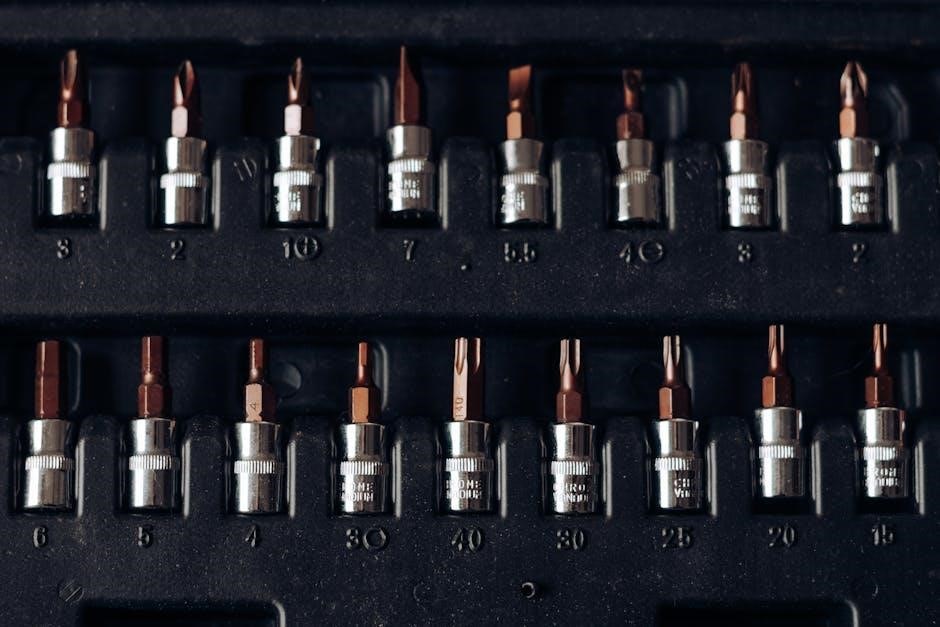

Essential tools include wrenches, sockets, and specialized transmission tools․ Key parts are the clutch kit, manual transmission, and pedal assembly․ Additional components may be required․

Essential Tools for the Job

The conversion requires a variety of tools, including wrenches, sockets, and specialized equipment like a transmission jack and clutch alignment tool․ A hydraulic clutch kit may be necessary, depending on the vehicle․ Additional tools such as a torque wrench, screwdrivers, and pliers are also needed․ Ensure all tools are compatible with your vehicle’s specifications to avoid complications during the process․

Key Components to Replace or Install

Replacing the automatic transmission with a manual gearbox is central to the conversion․ A clutch kit, including a clutch disc, pressure plate, and release bearing, must be installed․ The torque converter is removed and replaced with a flywheel․ Additionally, the shifter assembly, gear linkage, and transmission mounts must be installed or modified․ The accelerator pedal may need adjustment to accommodate the clutch pedal, ensuring proper functionality․

Step-by-Step Conversion Process

Converting an automatic to manual requires removing the automatic transmission, installing a manual gearbox, clutch system, and shifter․ Ensure proper alignment and connection of all components․

Removing the Automatic Transmission Components

Removing the automatic transmission involves disconnecting the torque converter, transmission mounts, and electrical connectors․ Draining the transmission fluid and detaching the driveshaft are essential steps․ Ensure the vehicle is securely lifted and supported to safely access and remove the automatic transmission assembly․ Properly label and store components for potential reuse or disposal․ This step requires precision to avoid damage to surrounding systems and components․

Installing the Manual Transmission and Linkage

Installing the manual transmission involves carefully aligning and mounting the gearbox, ensuring proper connection to the engine․ The clutch system must be integrated, with the clutch pedal and master cylinder installed․ Gear linkages, including the shift lever and cables, are connected to enable precise gear changes․ Proper alignment and secure mounting are critical for smooth operation․ Bleeding the clutch system and testing the linkage ensures functionality before finalizing the installation․

Legal and Licensing Considerations

Converting to manual may require legal approvals and a driver’s license upgrade․ Ensure compliance with local regulations and pass a manual transmission driving test if needed․

Obtaining Necessary Approvals

Converting an automatic to a manual transmission typically requires regulatory approval․ Authorities like the LTA may need documentation, including proof of parts compatibility and installation․ Ensure compliance with local vehicle standards․ Submit the modified vehicle for inspection to verify safety and legality․ Be prepared to provide detailed records of the conversion process․ Approvals ensure your vehicle meets all legal requirements and remains roadworthy after the conversion․

Upgrading Your Driver’s License

If your license is restricted to automatic transmissions, upgrading to a manual license is necessary after the conversion․ This typically requires passing a driving test in a manual vehicle․ Check with your local DMV or licensing authority for specific requirements․ Some jurisdictions may need proof of manual transmission training or a practical assessment․ Once approved, your license will be updated, allowing you to legally drive manual transmission vehicles․ This step ensures compliance with driving regulations and enhances your driving skills․

Maintenance and Upkeep After Conversion

Regular clutch and gearbox maintenance is essential for smooth operation․ Check transmission fluid, inspect clutch wear, and ensure proper linkage adjustment for optimal performance and longevity․

Clutch and Gearbox Maintenance Tips

Regular maintenance is crucial for the longevity of your manual transmission․ Check the clutch for wear and ensure the gearbox is properly lubricated with the correct fluid․ Inspect the linkage for smooth operation and adjust as needed․ Listen for unusual noises, as they can indicate impending issues․ Replace the clutch when it shows significant wear, and bleed the hydraulic system periodically to maintain optimal performance․ Addressing these areas ensures a smooth and reliable driving experience․

Addressing Common Post-Conversion Issues

Post-conversion issues may include uneven clutch engagement or difficulty shifting gears․ Check the linkage alignment and ensure proper pedal adjustment․ Lubrication levels must be verified, and any leaks addressed promptly․ If the transmission hesitates or makes unusual noises, inspect for worn components or improper installation․ Consulting a professional can resolve persistent problems, ensuring a smooth transition to manual operation and maintaining the vehicle’s reliability over time․

Converting an automatic to a manual transmission is a rewarding but complex process․ It requires meticulous planning, mechanical expertise, and significant investment․ While the result offers enhanced control and driving satisfaction, it’s crucial to weigh the costs and challenges against potential benefits․ For those passionate about driving, the effort can be worthwhile, transforming their vehicle into a more engaging and personalized machine․